Abrasive Cleaning

Heritage Consulting, Restoration and Execution...

Abrasive Cleaning

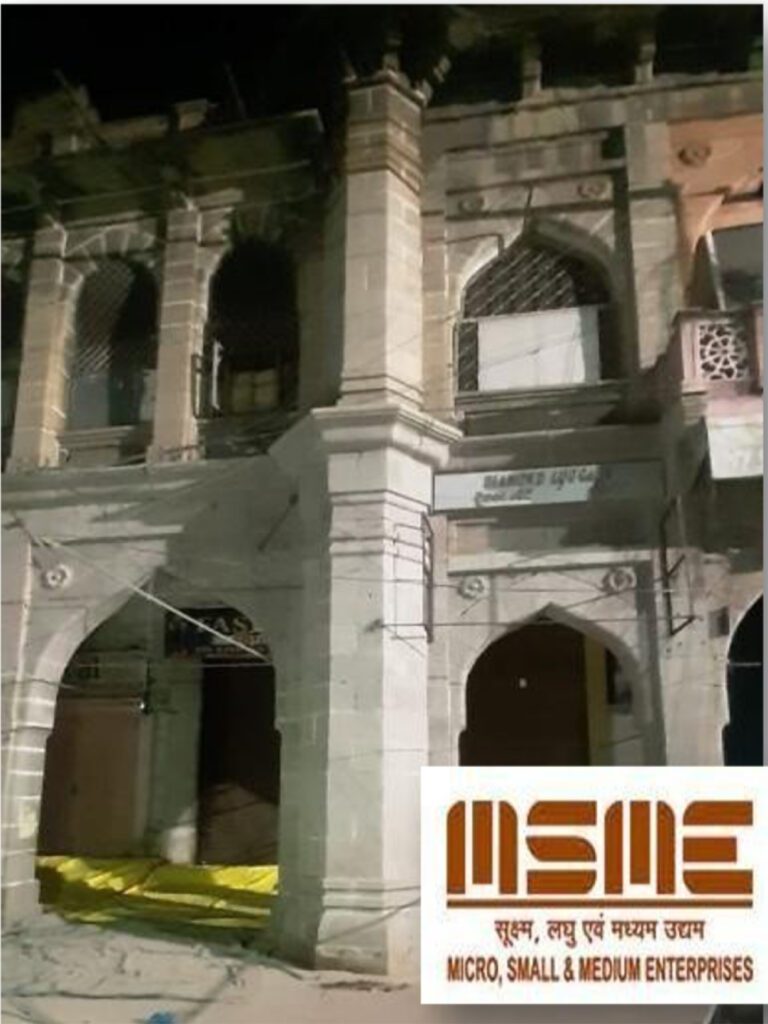

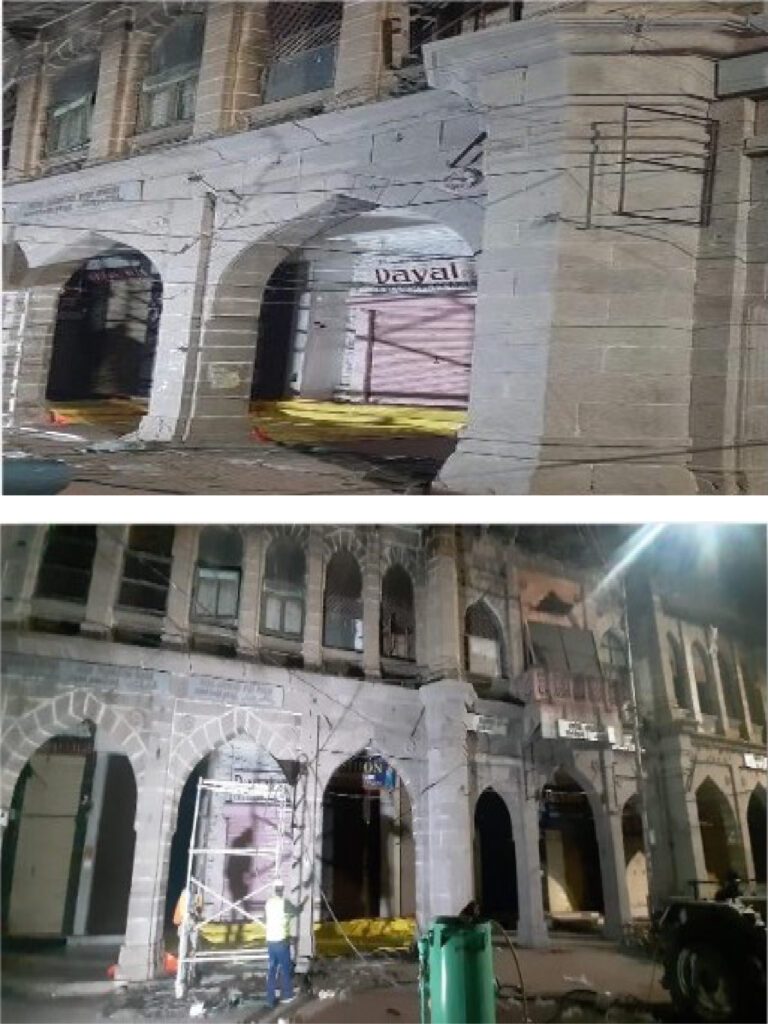

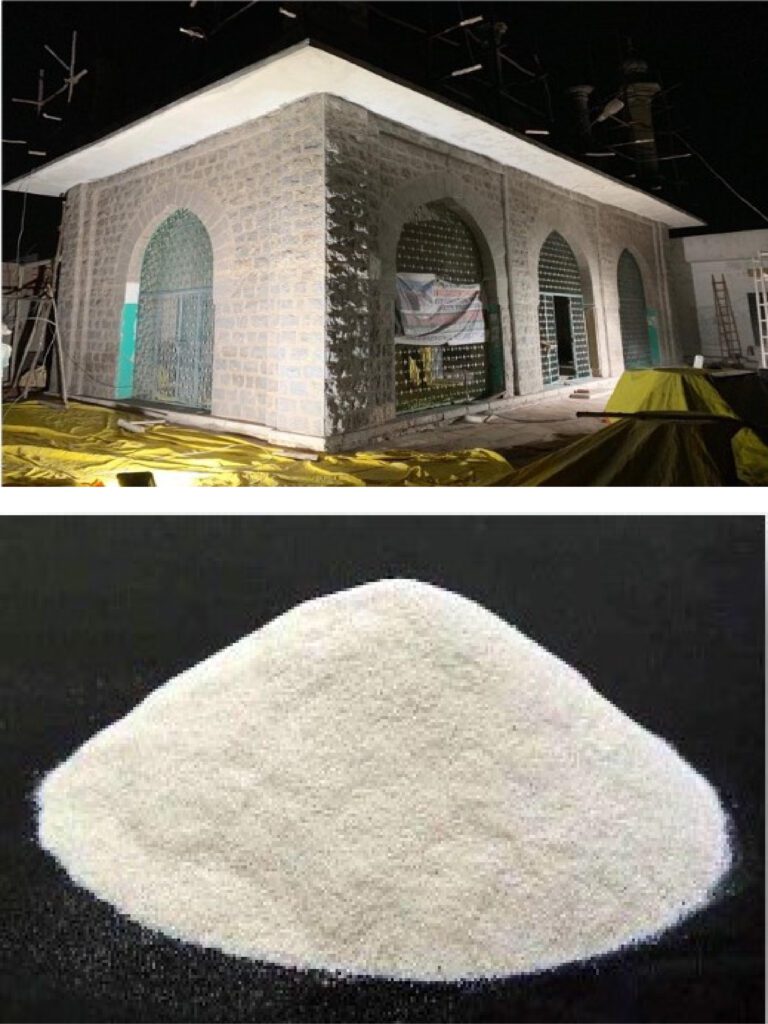

Abrasive is the operation of forcibly propelling a stream of abrasive material with air pressure against a surface. The sandblasting operation is done under high pressure to clean the old paints, durt, deterioration, contaminants,unwanted material, there is also a technique wherein rough surface is smoothened, smooth surfaces are sand blasted to get rough grain effect.

It is important to take opinion of an expert about the object, its porosity and take a decision of what media to be used in abrasive cleaning.

Sand Blasting process

Sandblasting is the process of effectively and powerfully impelling a stream of abrasive material against the surface under high pressure to smoothen the rough surface, alter the shape of the body or eradicate rusts, oil, pollution and contaminants of the surface, spontaneously and effectively.

Heritage Micro-blasting & Industrial Sand Blasting

• Surface preparation prior to painting, bonding or other coating operations

• Removal of rust, scale, sand, or paint from fabricated components

• Roughening of industrial gas turbine engine component surfaces in

preparation for thermal spray coating

• Removal of burrs or edge profiling machined components

• Providing a matte cosmetic surface finish on consumer products

• Removal of mold flash from plastic components

• Surface texturing of tooling, and molds to alter the appearance of molded or stamped products

It is important to take opinion of an expert about the object, its porosity and take a decision of what media to be used in abrasive cleaning.

Sand Blasting process

Sandblasting is the process of effectively and powerfully impelling a stream of abrasive material against the surface under high pressure to smoothen the rough surface, alter the shape of the body or eradicate rusts, oil, pollution and contaminants of the surface, spontaneously and effectively.

Heritage Micro-blasting & Industrial Sand Blasting

• Surface preparation prior to painting, bonding or other coating operations

• Removal of rust, scale, sand, or paint from fabricated components

• Roughening of industrial gas turbine engine component surfaces in

preparation for thermal spray coating

• Removal of burrs or edge profiling machined components

• Providing a matte cosmetic surface finish on consumer products

• Removal of mold flash from plastic components

• Surface texturing of tooling, and molds to alter the appearance of molded or stamped products

Materials on which Abrasive can be done:

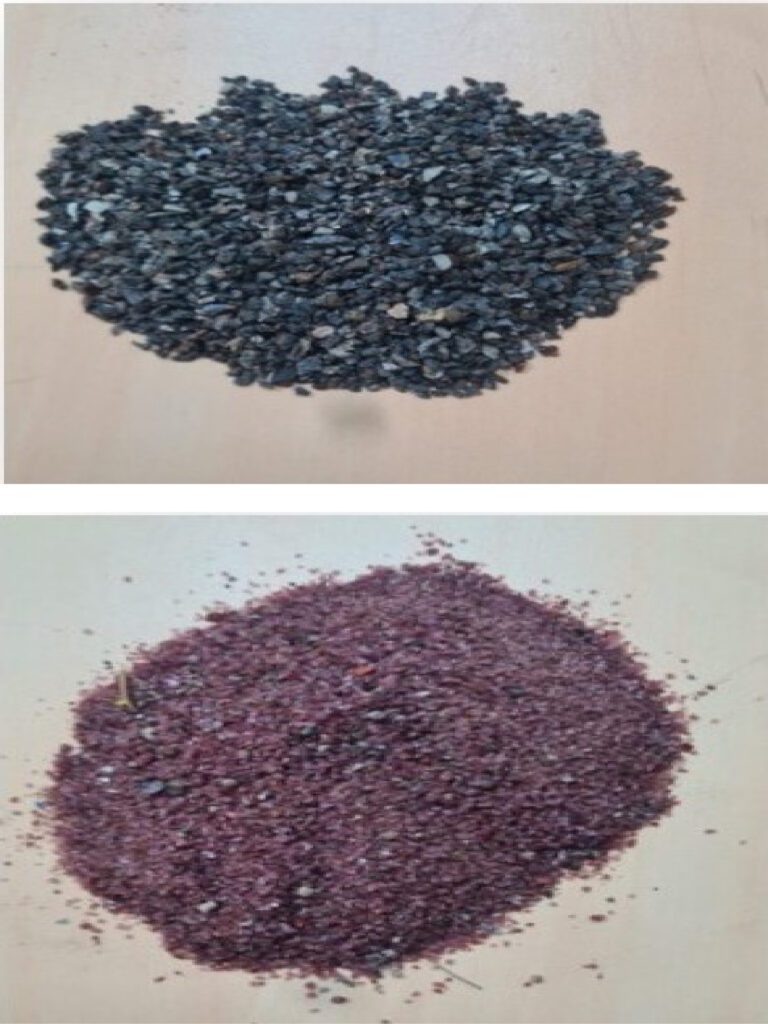

• Garnet &Aluminum Oxide – both these materials are most common for Shot Blasting, however for soft impact solutions, Aluminum oxide is most preferred abrasive.

Common Grit: - 20/40, 20/60 and 30/60 Fine grains of Abrasive garnet is recommended for blast cleaning applications.

• Dry Ice - Dry ice is made of reclaimed carbon dioxide that is produced from other industrial processes, and is an approved media by the EPA, FDA and USDA. It also reduces or eliminates employee exposure to the use of chemical cleaning agents.

• Walnut shell – Crushed walnut shell grit for deburring, de-flashing and finishing operations shell blast media is used for paint stripping and coatings removal deburring in aluminum, plastics, and zinc die casting industries De-flashing components in electronics industries, it is used in cleaning steam turbines aircraft / Aluminum engines

• Quartz Sand - (Silica sand) available in different grit, used as a mineral abrasive. Silica is a common abrasive used for medium to heavier sand blasting

• The pros (advantages) of sandblasting are as follows:

• Abrasive action on the surfaces: The abrasive materials which are being used in the process that have an aggressive action on the surfaces.

• Fit for rough surfaces: The powerful action of the sandblasting process can remove contaminants from the tough surfaces like a concrete.

• Quick Removal of contaminants: the sandblasting process helps for removing the deposits of the contaminants very quickly from the different surfaces.

• Less machinery is involved: Abrasive blasting does not involve the complex machinery for its process.

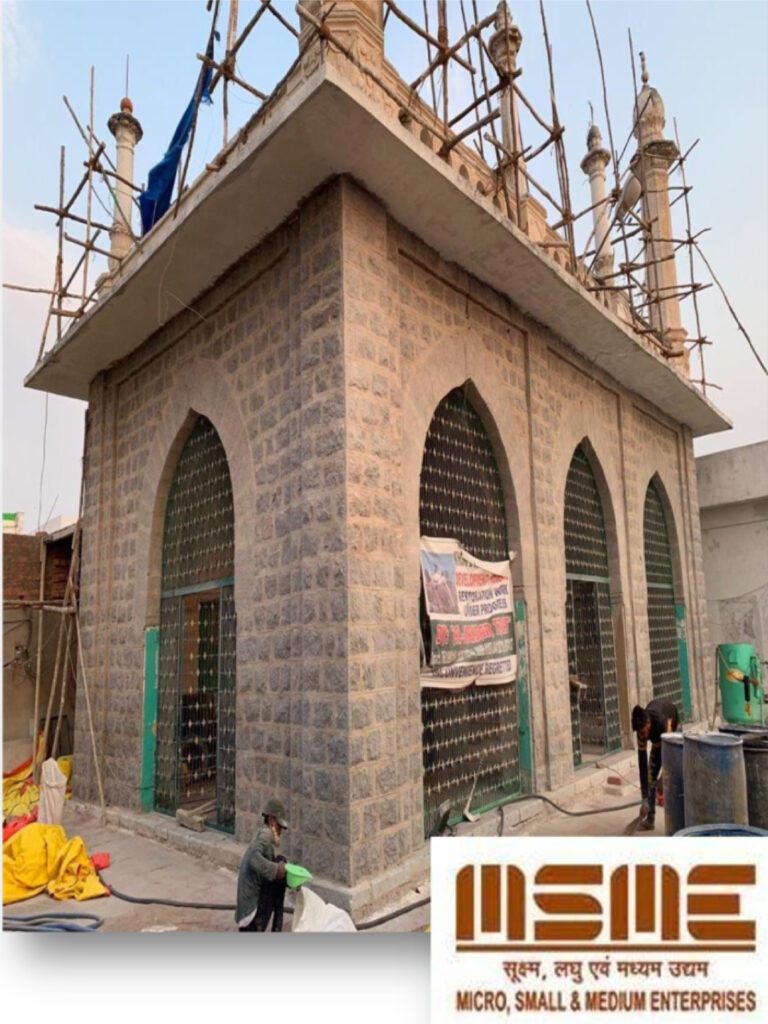

• Sand Blasting on stone :We can blast all types of stone, granite, etc. Basically, any type can be sandblasted but brittle stone like sandstone or porous surfaces may not be ideal. A quick look at the stone’s surface will give you an idea if it’s a good material for Sandblasting.

• A smoother surface is better because the stencil will stick to the rock better and prevent abrasive media from engraving in areas that you don’t want it to. While a more rough or porous surface will be harder for the stencil to stick

• Artifact Sand Blasting: We are also providing services for cleaning of large artifacts as, stone sculpture, metal sculpture wood sculpture, mural painting etc with the help of suitable material

• Sand Blasting on Metal: Sandblasting is a reliable practice to prepare a metal surface for bonding, adhesion, insert molding, painting, or other coating tasks or to achieve a specific surface texture. For instance, a matte finish texture of a metal surface instead of a shiny, smooth look.

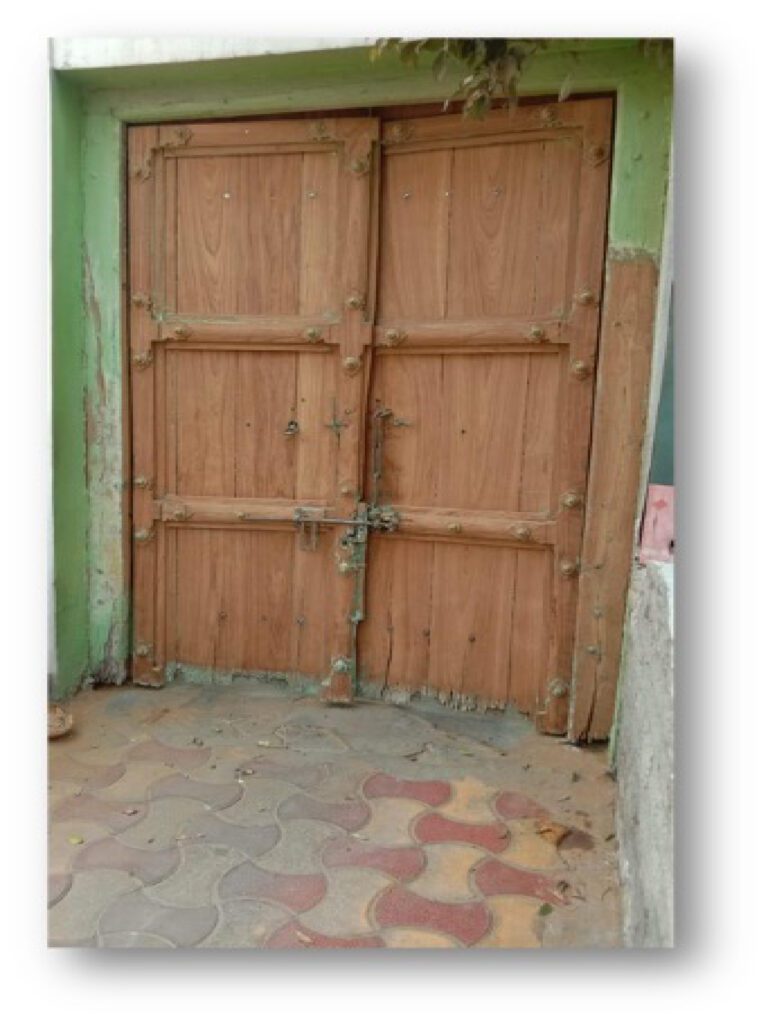

• Sand Blasting on Wood: Sandblasting is simply a process that involves propelling small particles such as bits of sand against a surface. And yes, sandblasting does work for removing the old paint from the wood as well. The abrasive particles will generally hit hard on the surface to remove paint that is sticking to the surface of the wood.

• Garnet &Aluminum Oxide – both these materials are most common for Shot Blasting, however for soft impact solutions, Aluminum oxide is most preferred abrasive.

Common Grit: - 20/40, 20/60 and 30/60 Fine grains of Abrasive garnet is recommended for blast cleaning applications.

• Dry Ice - Dry ice is made of reclaimed carbon dioxide that is produced from other industrial processes, and is an approved media by the EPA, FDA and USDA. It also reduces or eliminates employee exposure to the use of chemical cleaning agents.

• Walnut shell – Crushed walnut shell grit for deburring, de-flashing and finishing operations shell blast media is used for paint stripping and coatings removal deburring in aluminum, plastics, and zinc die casting industries De-flashing components in electronics industries, it is used in cleaning steam turbines aircraft / Aluminum engines

• Quartz Sand - (Silica sand) available in different grit, used as a mineral abrasive. Silica is a common abrasive used for medium to heavier sand blasting

• The pros (advantages) of sandblasting are as follows:

• Abrasive action on the surfaces: The abrasive materials which are being used in the process that have an aggressive action on the surfaces.

• Fit for rough surfaces: The powerful action of the sandblasting process can remove contaminants from the tough surfaces like a concrete.

• Quick Removal of contaminants: the sandblasting process helps for removing the deposits of the contaminants very quickly from the different surfaces.

• Less machinery is involved: Abrasive blasting does not involve the complex machinery for its process.

• Sand Blasting on stone :We can blast all types of stone, granite, etc. Basically, any type can be sandblasted but brittle stone like sandstone or porous surfaces may not be ideal. A quick look at the stone’s surface will give you an idea if it’s a good material for Sandblasting.

• A smoother surface is better because the stencil will stick to the rock better and prevent abrasive media from engraving in areas that you don’t want it to. While a more rough or porous surface will be harder for the stencil to stick

• Artifact Sand Blasting: We are also providing services for cleaning of large artifacts as, stone sculpture, metal sculpture wood sculpture, mural painting etc with the help of suitable material

• Sand Blasting on Metal: Sandblasting is a reliable practice to prepare a metal surface for bonding, adhesion, insert molding, painting, or other coating tasks or to achieve a specific surface texture. For instance, a matte finish texture of a metal surface instead of a shiny, smooth look.

• Sand Blasting on Wood: Sandblasting is simply a process that involves propelling small particles such as bits of sand against a surface. And yes, sandblasting does work for removing the old paint from the wood as well. The abrasive particles will generally hit hard on the surface to remove paint that is sticking to the surface of the wood.